Which V-Type Engine Valve Train Design May Use Four Camshafts?

In the world of automotive engineering, there are several different types of engine valve train designs that can be used in V-type engines. However, one particular design that stands out is the one that utilizes four camshafts. This may come as a surprise to many, as it is not a commonly seen configuration. But, in certain high-performance V-type engines, such as those found in sports cars or racing vehicles, four camshafts can offer numerous advantages and unique capabilities.

The use of four camshafts in a V-type engine valve train design provides precise control over the intake and exhaust valves. This allows for enhanced engine performance and efficiency, as well as improved power output. Additionally, the four-camshaft design enables better airflow through the engine, resulting in improved fuel combustion and reduced emissions. This sophisticated configuration has proven to be highly effective in maximizing the potential of V-type engines, making it a preferred choice for high-performance vehicles.

A V-type engine valve train design that may use four camshafts is the Double Overhead Camshaft (DOHC) design. In this configuration, each cylinder head has two camshafts: one for the intake valves and one for the exhaust valves. This allows for precise control of valve timing and improves engine performance. The use of four camshafts also enables a higher rev limit and enhances the engine’s responsiveness. Overall, the DOHC design with four camshafts is commonly found in high-performance V-type engines.

Introduction: Understanding V-Type Engine Valve Train Design

A V-type engine is a piston engine configuration in which the cylinders are arranged in a V shape, commonly at a 60 or 90-degree angle. This configuration is popular for its compact size, balance, and efficiency. One crucial component of a V-type engine is the valve train, which controls the opening and closing of the valves.

The valve train design of an engine plays a significant role in optimizing the engine’s performance and efficiency. While many V-type engines use a single camshaft to operate the valves, there are certain designs that employ four camshafts. These engines with four camshafts offer unique advantages in terms of valve control, power output, and versatility.

High-Performance V8 Engines

One type of V-type engine valve train design that may use four camshafts is found in high-performance V8 engines. These engines are often used in sports cars, muscle cars, and high-performance luxury vehicles. By employing four camshafts, these engines can achieve precise valve timing and control, allowing for optimal power delivery and performance.

With two camshafts per cylinder bank, these engines can independently control the intake and exhaust valves, maximizing efficiency and airflow. The use of four camshafts also enables variable valve timing, which can further enhance performance by adjusting valve timing for different engine speeds and loads.

In high-performance V8 engines, the use of four camshafts allows for more aggressive valve lift profiles and higher lift rates, resulting in improved airflow into and out of the combustion chambers. This enhances power output and contributes to the engine’s overall performance.

Formula One Engines

Another V-type engine valve train design that utilizes four camshafts is found in Formula One engines. These engines are the pinnacle of automotive engineering, designed for maximum performance and efficiency in racing conditions.

Formula One engines require precise valve control to achieve high RPMs and power output. By using four camshafts, these engines can achieve exceptional valve timing accuracy and control, allowing for rapid combustion and efficient power delivery.

The use of four camshafts in Formula One engines enables independent control of intake and exhaust valves, ensuring optimal airflow and combustion efficiency. This valve train design also allows for advanced technologies such as variable valve lift and timing, which further optimize engine performance under varying conditions.

Marine and Industrial Engines

In addition to high-performance automotive applications, V-type engines with four camshafts are also used in marine and industrial applications. These engines are designed to deliver exceptional power and durability in demanding environments.

Marine engines, which power boats and watercraft, require reliable performance and efficient power delivery in harsh conditions. By utilizing four camshafts, these engines can optimize valve timing for different operating conditions, ensuring smooth acceleration and enhanced fuel efficiency.

Industrial engines, such as those used in power generation or large machinery, also benefit from the use of four camshafts. These engines require high torque output and reliability. With four camshafts, the valve timing and control can be precisely calibrated to meet the specific power demands of industrial applications.

Advantages of Four Camshaft Designs

The use of four camshafts in V-type engine valve train designs offers several advantages over single camshaft configurations. These advantages include:

- Improved Valve Control: Four camshafts allow for precise control of intake and exhaust valves, optimizing airflow and combustion efficiency.

- Variable Valve Timing: With four camshafts, engines can benefit from variable valve timing, adjusting valve openings for different engine speeds and loads.

- Enhanced Power Output: The ability to independently control intake and exhaust valves, combined with aggressive valve lift profiles, can result in improved power output.

- Versatility: Four camshaft designs can be adapted to different applications, from high-performance vehicles to marine and industrial engines.

Exploring Different V-Type Engine Valve Train Designs with Four Camshafts

Aside from high-performance V8 engines, Formula One engines, and marine and industrial applications, there are other V-type engine valve train designs that may also use four camshafts. Let’s explore a few more:

V12 Engines

V12 engines, commonly used in luxury and high-performance vehicles, may employ four camshafts for precise valve control and power delivery. With two camshafts per cylinder bank, V12 engines can optimize intake and exhaust valve timing, resulting in exceptional performance and smooth power delivery.

The use of four camshafts in V12 engines also allows for advanced technologies such as variable valve lift and timing, improving efficiency and power output. The combination of a V12 configuration and four camshafts makes these engines capable of delivering impressive performance and refinement.

Diesel Engines

Some diesel engines with a V-type configuration also make use of four camshafts. Diesel engines depend on precise fuel injection and combustion control for optimal performance and efficiency.

With four camshafts, diesel engines can achieve fine control over valve timing and lift, allowing for efficient combustion and reduced emissions. The increased flexibility in valve control enables diesel engines to adapt to varying driving conditions and deliver responsive performance.

Custom Performance Engines

Custom performance engines, designed for specific applications or modified vehicles, may also utilize four camshafts for unique performance characteristics. These engines are often tailored to meet the specific requirements and goals of enthusiasts and performance specialists.

By employing four camshafts, custom performance engines can achieve precise valve timing and control, enhancing power delivery and optimizing performance for specific applications, such as drag racing, street performance, or off-road use.

Conclusion

V-type engine valve train designs that utilize four camshafts offer significant advantages in terms of valve control, power output, and versatility. From high-performance V8 engines to Formula One engines, marine and industrial applications, V12 engines, diesel engines, and custom performance engines, the use of four camshafts allows for precise valve timing, enhanced power delivery, and optimized performance. Whether for sports cars, luxury vehicles, boats, or custom applications, engines with four camshafts provide engineers and enthusiasts with the tools to achieve exceptional performance in various settings.

Which V-Type Engine Valve Train Design May Use Four Camshafts?

In the world of automotive engineering, certain high-performance V-type engines may employ an advanced valve train design that utilizes four camshafts. This configuration allows for improved control and precision in the engine’s valve operations, resulting in enhanced power and efficiency.

A V-type engine consists of two banks of cylinders arranged in a V-shape. Each bank has its own set of camshafts, typically one for the intake valves and one for the exhaust valves. However, in some cases, particularly in high-performance engines, each bank may feature two camshafts for the intake and exhaust valves separately.

The use of four camshafts in a V-type engine valve train design allows for greater control over the valve timing and duration, optimizing the engine’s performance across various RPM ranges. This design also enables a more efficient intake and exhaust flow, leading to improved combustion and power delivery.

Key Takeaways: Which V-Type Engine Valve Train Design May Use Four Camshafts?

- A V-type engine with a four-camshaft valve train design can be used.

- This design is commonly found in high-performance engines.

- Having four camshafts allows for precise control of the engine’s valve timing and lift.

- Each camshaft is responsible for operating a set of intake and exhaust valves.

- Four camshafts enable better engine efficiency and power output.

Frequently Asked Questions

When it comes to V-type engine valve train designs, there are various configurations that can be used. One of these configurations involves the use of four camshafts. Below, we’ve answered some frequently asked questions about this particular valve train design.

1. How does a V-type engine valve train work?

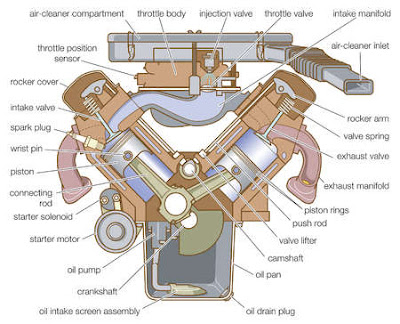

The valve train in a V-type engine is responsible for controlling the intake and exhaust valves for each cylinder. It consists of components such as camshafts, lifters, pushrods, and rocker arms. The camshafts, which are driven by the engine’s crankshaft, open and close the valves at the correct times and durations, allowing the engine to intake air and fuel and expel exhaust gases.

By using a V-shape configuration, the engine can have two cylinder banks that are angled apart. This design allows for better space utilization and can result in higher engine performance.

2. What is the purpose of using four camshafts in a V-type engine valve train design?

A V-type engine with four camshafts typically uses two camshafts per cylinder bank. These additional camshafts provide more control over the valve timing and lift, allowing for improved performance and efficiency.

With four camshafts, specific valve timing can be achieved for each cylinder bank, optimizing power delivery and fuel economy. The four-cam configuration also reduces the load on each individual camshaft, allowing for higher engine speeds and overall performance.

3. What are the advantages of a V-type engine valve train design with four camshafts?

The use of four camshafts in a V-type engine valve train design offers several advantages:

– Improved control over valve timing and lift, enhancing engine performance and efficiency.

– Optimal power delivery and fuel economy for each cylinder bank.

– Reduced load on individual camshafts, enabling higher engine speeds and overall performance.

4. Are there any downsides to using four camshafts in a V-type engine valve train design?

While a valve train design with four camshafts offers numerous benefits, there are also some potential downsides:

– Increased complexity and cost of manufacturing, as four camshafts and their associated components are needed.

– Additional weight due to the presence of extra camshafts and related components.

– Higher maintenance requirements, as more camshafts need to be checked and adjusted periodically.

5. Which V-type engine valve train designs commonly use four camshafts?

While not all V-type engine valve train designs utilize four camshafts, some specific configurations that may incorporate this setup include:

– DOHC (Dual Overhead Cam) designs with two camshafts per cylinder bank.

– QUAD camshaft designs with four camshafts, distributed between the two cylinder banks.

Which is the Best Engine Valvetrain Design? OHV, SOHC, DOHC or Flathead | Pros and Cons

In conclusion, the valve train design of a V-type engine that may use four camshafts is the DOHC (Dual Overhead Camshaft) design. This design features two camshafts per cylinder bank, allowing for precise control over the intake and exhaust valves.

By utilizing four camshafts, the DOHC design ensures optimal engine performance and efficiency. Each set of camshafts is responsible for operating the intake and exhaust valves separately, resulting in improved airflow and combustion. With this design, the engine can achieve higher power output and better fuel economy.

Home - Which V-Type Engine Valve Train Design May Use Four Camshafts?